Reklamepartner Graphics in Sofiemyr, south of the Norwegian capital Oslo, has doubled down and invested in two large-format printers from Agfa. As they already had one, this means that almost all their prints are now produced on Agfa machines.

“Agfa has excellent production machines, and it’s a significant advantage for us to have a one-stop-shop. It means we have an overall service agreement and a single workflow solution, and that all operators can easily switch from one machine to another,” says CEO Gisle Nesbakk about the decision.

Reklamepartner Graphics was established by Nesbakk in 1998. Ten years later, the company was acquired by Norwegian New Store Europe, which provided retail solutions to specialty stores. When New Store Europe went bankrupt nine years ago, the Swedish group ITAB acquired the company, which also included Reklamepartner, although they were a separate company that did not go bankrupt. ITAB is headquartered in Jönköping and sells in-store decoration, primarily in-house developed checkout counters found in many stores in the Nordic countries.

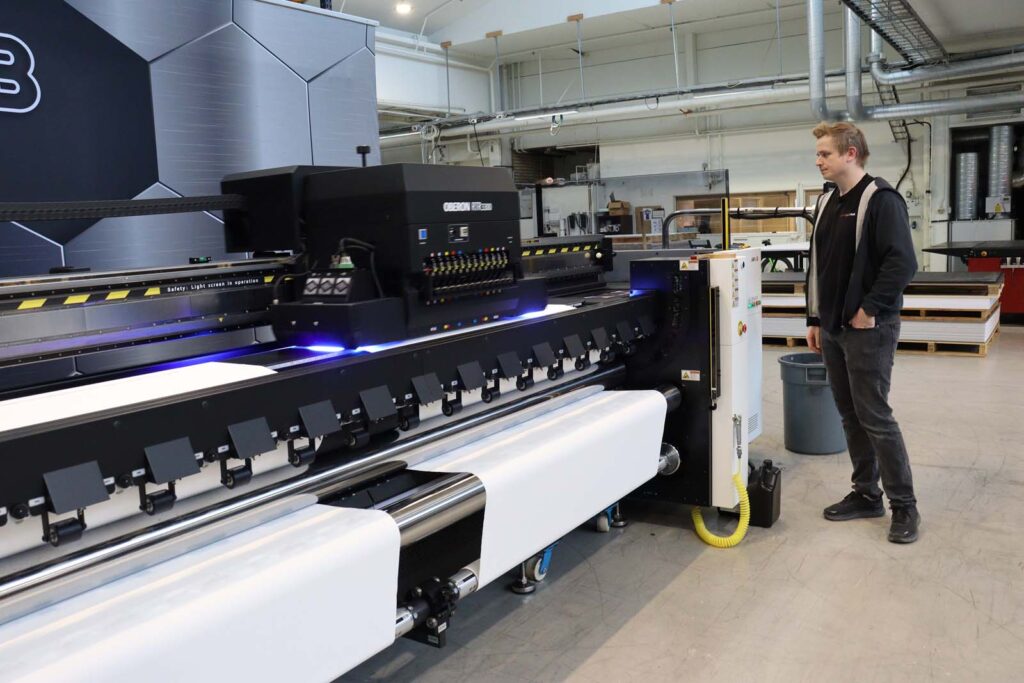

Nils-Arne Sletten from Agfa and Gisle Nesbakk from Reklamepartner Graphics in front of the Oberon machine, which is used to print wallpaper

Reklamepartner is a ‘pure factory’ for ITAB and produces signs and other graphic materials for stores that are newly opened or get a makeover. So it’s not about materials for temporary campaigns, but more about permanent interior design. Some of the company’s customers are major chains like Coop or Power.

It all started with a Tauro

Agfa’s Jeti Tauro H2500 LED still has a lot to offer despite its seven years. During that time, Reklamepartner has not had to change the printhead once.

Around the same time that New Store Europe collapsed and Reklamepartner got a new owner, it was high time to replace two old Durst printers. Coincidentally, Agfa’s sales rep Nils-Arne Sletten walked in the door just then. “It was seven years ago, and we have had a very good cooperation since then,” says Nils-Arne Sletten.

The meeting ended with a deal: Agfa’s hybrid Jeti Tauro H2500 LED with white ink and ¾ automation with automatic feeder and stacker. The agreement was signed shortly after Fespa in May 2017, and the installation was carried out later that fall. The printer still plays a crucial role in production.

“We haven’t changed the printhead once in seven years,” says Gisle Nesbakk, adding that it was probably relevant when the decision was made to buy more Agfa machines.

“Extremely impressed”

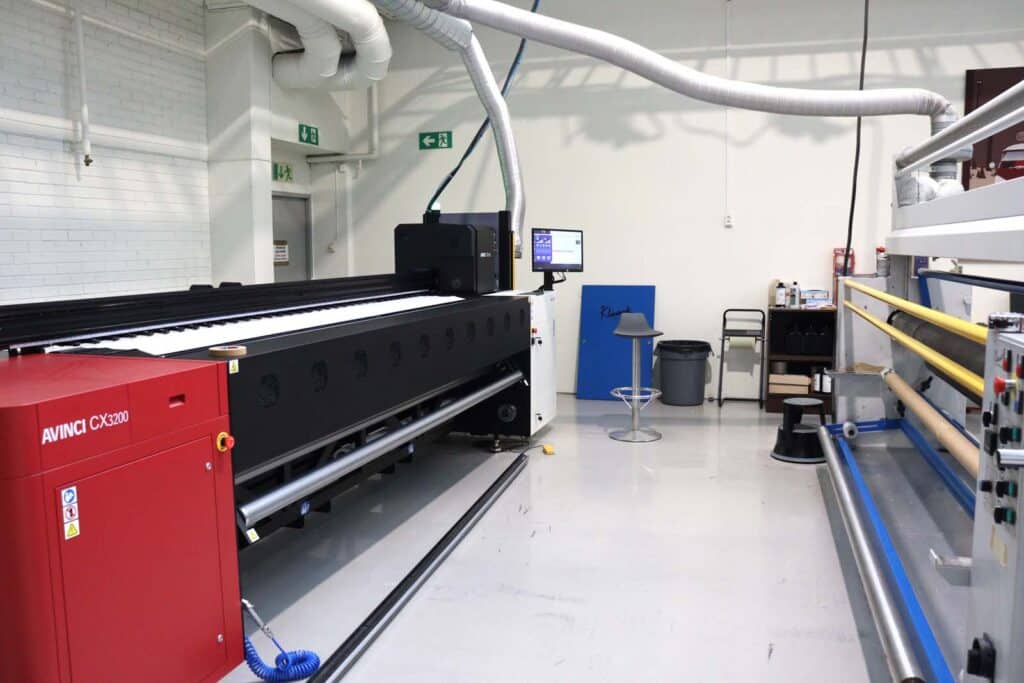

Last year it was time to upgrade the machinery again, and an old Durst Rhotex had served its purpose after twelve years. The replacement was another sublimation printer, Agfa’s Avinci CX3200, with an offline calendar machine. It is an inkjet printer for soft signage and interior decoration, both for indoor and outdoor use with widths up to 3.2 meters. It prints directly onto the fabric or transfer paper and can do so at a speed of up to 250 square meters per hour.

Reklamepartner still has its own sewing room where mainly rubber strips are sewn onto textile applications.

But it doesn’t stop with the Avinci. An Oberon RTR 3300 roll-to-roll with UV LED has also moved into the premises. It prints anything from wallpapers to magnetic foils and regular vinyl, but also canvases for lightboxes, including Samba backlit. In addition to CMYK, it also has light magenta and light cyan for a larger color gamut and better print quality. A truly high-end machine that combines extreme productivity with high-quality prints.

“Agfa now accounts for almost all our printing. The only exception is a Canon Colorado,” says Gisle Nesbakk.

The Oberon RTR3300 roll-to-roll printer can also print on textiles, for example, fabric for lightboxes.

Cutting for every line

Both machines were installed in November 2023 and are now in production after some fine-tuning and staff training. All three Agfa machines are powered by Agfa’s workflow software Asanti, which takes care of color management and simplifies and automates the process from prepress and printing to finishing.

As mentioned, the Jeti Tauro is still an essential part of production. It is used, among other things, to create hanging signs, canopies, frames, and larger standing signs in Reboard. The material is then cut on one of Reklamepartner’s three Kongsberg tables.

“We have one cutting table per line so that one operator can handle the entire workflow. We are also pilot customers for Kongsberg and get to test new products,” says Gisle.

Complete workshop

In addition, there are two MultiCam tables for milling LED boxes and signs. Reklamepartner produces everything itself and therefore has a complete workshop with all conceivable tools for sign production, including a small paint shop.

“We do everything ourselves. If there are large series of e.g., fittings, we have a subcontractor in Trondheim who does it, but we produce everything that is smaller series here. That’s the difference between us and a regular graphic company that only deals with printing.

Working on large projects like rebranding store chains leads to peaks in work, but also quieter periods for the seven employees in total.

“We would like to have more external customers between the major projects. Previously, all ITAB companies had the same website, but now we are developing our own website, so we won’t be so anonymous anymore. So hopefully more customers can find us," says Gisle Nesbakk.

Reklamepartner Graphics is owned by the Swedish group ITAB, which produces store fixture solutions.

The Avinci sublimation printer with a separate calendar unit and cutting table connected.

The preceding press release was provided by a company unaffiliated with Wide-format Impressions. The views expressed within do not directly reflect the thoughts or opinions of Wide-format Impressions.

Nikki Levy Interiors Deploys Roland DG DIMENSE for Custom 3D Interiors

Nikki Levy Interiors Deploys Roland DG DIMENSE for Custom 3D Interiors

Vanguard Digital Printing Systems Announces State-Of-The-Art Experience Center

Vanguard Digital Printing Systems Announces State-Of-The-Art Experience Center

Roland DG's Andrew Oransky on New Printers, Monza Event

Roland DG's Andrew Oransky on New Printers, Monza Event

Roland DG Grand Print Event Highlights Next-Level Systems

Roland DG Grand Print Event Highlights Next-Level Systems

New Extension Tables Now Available for Roland's TrueVIS LG Series

New Extension Tables Now Available for Roland's TrueVIS LG Series

Why Wide-Format Printing Makes Sense for Promotional Products Suppliers

Why Wide-Format Printing Makes Sense for Promotional Products Suppliers