Mimaki has developed its first direct-to-film (DTF) printer, the TxF150-75 and the heat transfer pigment ink, PHT50 for DTF, and will start selling them in April 2023, targeting the textile and apparel printing applications. Prior to the sales launch of the new products, the new model will be exhibited for the first time in the world at Printwear & Promotion Live! (Birmingham, UK), an exhibition to be held from Feb. 26, 2023.

DTF printing is a printing method that has become widespread in the textile and apparel industry, especially in the wear printing market typified by T-shirts. In DTF printing, the design is first printed directly on a special transfer film by a printer. Next, the printed film is sprinkled with hot-melt powder, which is then heated and dried to form a transferable ink layer on the film. The formed ink layer is then transferred to a fabric such as a T-shirt by a heat press to complete the finished product.

The TxF150-75, developed by Mimaki Engineering, is an inkjet printer with a maximum printing width of 80 cm for producing DTF print transfer sheets. The PHT50 heat transfer pigment ink for DTF, consisting of five colors (CMYK and white), is scheduled to obtain the ECO PASSPORT certification by the end of March which is essential for obtaining the international safety standard for textile products “OEKO-TEX”.

The DTF printers have been plagued by ink ejection defects and white ink clogging. To overcome these issues, Mimaki has adopted a degassing ink design that uses aluminum packs as the printer's ink packaging form, as well as a white ink circulation function MCT (Mimaki Circulation Technology)*1. The new printer also features Mimaki's NCU (Nozzle Check Unit)*2 and NRS (Nozzle Recovery System)*3 technologies that support stable operation. They ensure continuous printing without stopping the operation to support customers' productions.

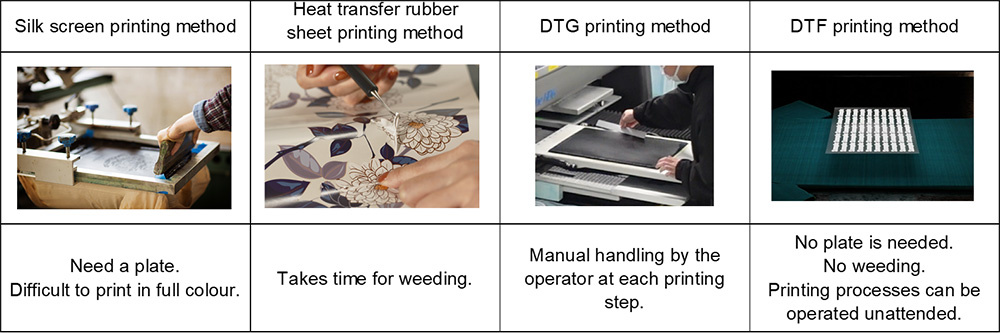

Currently, silk screen printing is widely used in the wear printing market, but this printing method requires the preparation of plates, making it unsuitable for small-lot production. Moreover, full-color printing requires time and labor to create plates for each color. The heat transfer method using rubber sheets is also commonly used, but it involves manual labor for "weeding," which is the process of manually removing unnecessary portions of the transfer when fixing the printed design on the fabric. In recent years, there has also been a growth of direct-to-garment (DTG) printing, which uses inkjet printers to print designs directly on garments and fabrics. DTG printing does not require plates and can be used for full-color printing, but it does require fabric preprocessing and manual handling by the operator at each printing steps.

Under these market circumstances, DTF printing eliminates the need for plate preparation and weeding, which have been difficulties in conventional printing methods. Since it enables unattended printing process operation, it is rapidly being adopted in the market as a technology that contributes to labor savings.

The TxF150-75 is scheduled to go on sale in April 2023 and our offerings for DTF printing will be printers, inks and RIP software.

Our recommended specifications for the film used to create the transfer sheet, hot-melt powder, powder application equipment, post-processing machines and heat press transfer machines are provided to customers at the time of sale.

With "Something New, Something Different" as our management vision, Mimaki Engineering will continue to pursue new technological innovations constantly and to realize the "beauty and speed" that our customers demand.

The preceding press release was provided by a company unaffiliated with Wide-format Impressions. The views expressed within do not directly reflect the thoughts or opinions of Wide-format Impressions.

Mimaki USA Unveils Two New Digital Textile Printers

Mimaki USA Unveils Two New Digital Textile Printers

Exploring The Apparel Decoration Opportunity

Exploring The Apparel Decoration Opportunity

Epson Announces its First Direct-to-Film Printer

Epson Announces its First Direct-to-Film Printer

Direct-to-Fabric Printing with Hybrid Sublimation Inkjet Printers

Direct-to-Fabric Printing with Hybrid Sublimation Inkjet Printers

Revenue Surges After In-plant Adds DTF Printer

Revenue Surges After In-plant Adds DTF Printer

Epson Wins Prestigious 2024 Red Dot Design Awards Across Four Product Lines

Epson Wins Prestigious 2024 Red Dot Design Awards Across Four Product Lines